Automatic Steel Wheel Rim Production Machines

-

- Coiling Machine (with Automatic Loading System)

Wheel rim coiler machine used in steel wheel production line to form coiled hoops from flat strips

The wheel rim coiling machine is an essential piece of equipment in steel wheel production, designed to form flat steel strips into coiled hoops efficiently. Its automatic loading system optimizes the production of wheel rims by feeding the steel strips into the machine and ejecting coiled rims without manual intervention, reducing labor and improving workflow. This advanced coiling machine integrates three primary components to ensure precision shaping and high productivity: stamping, coiling and flattening.

-

- Butt Welding Machine

Flash butt welder used in the steel wheel production line for welding steel wheel rims

The butt welding machine used in steel wheel production line is designed for joining and welding the ends of the coiled hoops together to form wheel rims. Both clamping and welding functions are operated hydraulically, with welding parameters easily adjustable via a touch screen.

-

- Trimming, Planishing, End Cutting and Re-rounding Machine

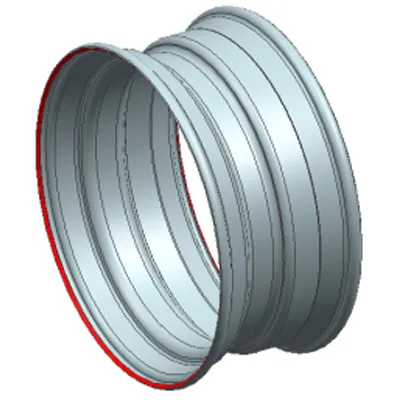

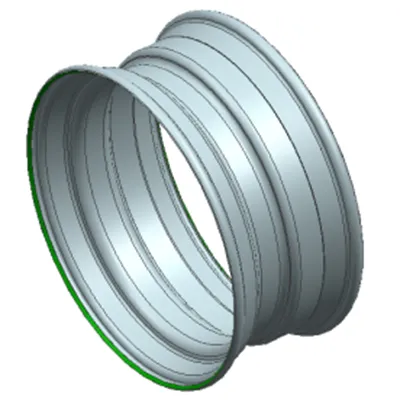

Weld trimmer, weld seam planisher, end cutting and re-rounder for handling steel wheel rim after butt welding operation

The trimming, planishing, end cutting, and re-rounding machine is a specialized piece of equipment for processing steel wheel rims after the butt welding stage. It includes multiple integrated components: weld trimmer, weld slag remover, weld seam planisher, and end cutting, along with an automated loading and unloading system, ensuring efficient handling of welded rims.

-

- Horizontal Flaring Machine

Wheel rim machine used in steel wheel production line prior to the roll forming process

The horizontal flaring machine is used in the steel wheel production line to perform the initial flaring of the coiled and welded hoop to start the rim profiling operation. Also known as a flare press, it flares both sides of the welded and trimmed rim that helps shape the rim accurately, ensuring a smooth transition in the roll forming process.

-

- Cone Expansion Rim Flaring Machine The cone expansion flaring machine is a dedicated piece of equipment designed for wheel rim flaring operations. It expands both sides of a welded and trimmed wheel rim into a bell-mouth profile, creating the required geometry for subsequent rim rolling and forming operations.

-

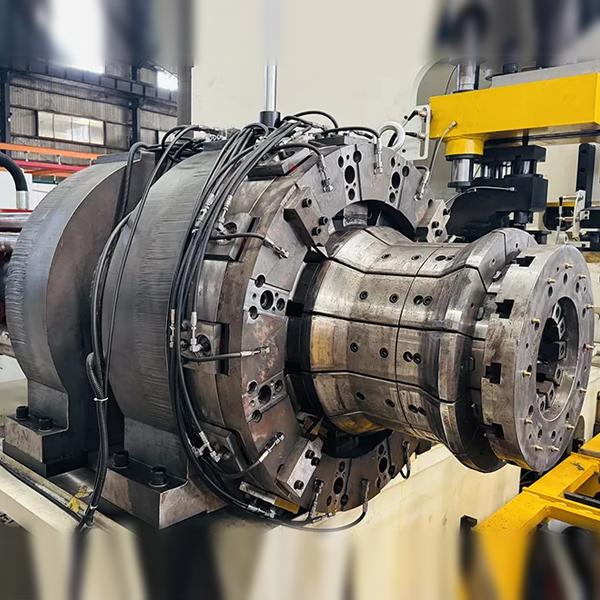

- Roll Forming Machine

Wheel rim profiling machine used in steel wheel production line following the flaring operation

Following the flaring process, the rim band enters the first of typically three roll forming machines, where it is progressively shaped to its intended rim profile. The roll forming machine is used in steel wheel production to size wheel rims through a precise cold-forming process, that profiles both symmetrical and asymmetrical rim designs, accommodating diverse specifications and styles. Powered by a fully hydraulic system, the rim roller ensures smooth and efficient rim shaping, achieving the final contours required for high-quality wheel rims in an efficient wheel production line.

-

- Rim Edge Deburring Machine The fully automatic edge deburring machine is a dedicated solution for rim edge deburring in wheel rim manufacturing. Designed for post-forming operations, the machine removes burrs from both rim flanges in a single pass, producing smooth edges with no visible burrs. The system consists of four main functional modules: a feeding unit, alignment unit, powered rim rotation unit, and powered deburring unit with grinding heads. With PLC-based control, the machine supports manual, semi-automatic, and fully automatic operating modes, ensuring flexible integration into different production lines.

-

- Horizontal Expanding Machine

Wheel rim expanding machine used in steel wheel production line to size the wheel rim

The horizontal expanding machine is used in the steel wheel production line to expand and size wheel rims after the roll forming process. It is composed of three main parts: the main unit, hydraulic power system, and control panel, all interconnected for synchronized operation. Equipped with features like stroke completion sensors and pressure relays, the wheel rim expander press allows precise control over working pressure, speed, and stroke length, which can be adjusted to meet specific production requirements.

-

- Valve Hole Punching Machine

Wheel rim valve hole machine for accomplishing operations of flattening (coining), punching and deburring

The valve hole punching machine is used in wheel rim production line to perform flattening (coining), punching, and deburring operations on the rim, ensuring precise and clean valve hole formation on a pre-defined position. It is composed of four main sections: the flattening machine, punching machine, deburring machine, and an automated loading/unloading system, which work together to automate the valve hole punching process.

-

- Air Leak Testing Machine

Leak detector used in steel wheel production line to determine small leaks in the weld zone

After the rim is fully formed, it passes through the air leak testing machine, which is specialized equipment in the steel wheel production line designed to detect any small holes and cracks in the weld area of wheel rims. This leak detector comprises three main sections: the mechanical unit, hydraulic power system, and electrical control system. These components are integrated via electrical connections to ensure synchronized operation, allowing for precise and reliable detection of even the smallest leaks in the weld area.