Valve Hole Punching Machine

Wheel rim valve hole machine for accomplishing operations of flattening (coining), punching and deburring

Valve Hole Punching Machine

Wheel rim valve hole machine for accomplishing operations of flattening (coining), punching and deburring

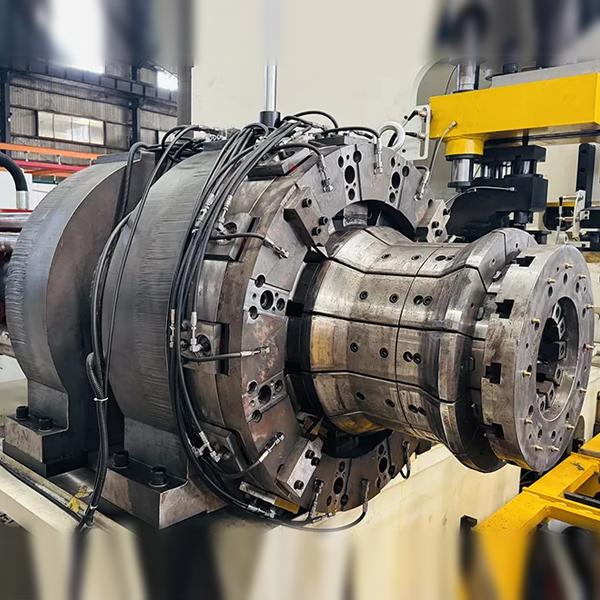

The valve hole punching machine is used in wheel rim production line to perform flattening (coining), punching, and deburring operations on the rim, ensuring precise and clean valve hole formation on a pre-defined position. It is composed of four main sections: the flattening machine, punching machine, deburring machine, and an automated loading/unloading system, which work together to automate the valve hole punching process.

Component Functions

- The valve hole flattening (coining) machine creates a small flat surface on the rim where the valve hole will be positioned. This flat area improves the valve’s seal, preventing potential air leaks.

- The valve hole punching press drills a small, precise hole in the center of the flattened area, providing an exact fit for the valve stem.

- The valve hole deburring press removes any burrs or sharp edges around the valve hole, ensuring a smooth finish to prevent scratches or damage to the valve stem and its sealing components.

- The automatic loading and unloading system coordinate the operation of all three main components, enhancing efficiency of the valve hole punching process for wheel rims.