Trimming, Planishing, End Cutting and Re-rounding Machine

Weld trimmer, weld seam planisher, end cutting and re-rounder for handling steel wheel rim after butt welding operation

Trimming, Planishing, End Cutting and Re-rounding Machine

Weld trimmer, weld seam planisher, end cutting and re-rounder for handling steel wheel rim after butt welding operation

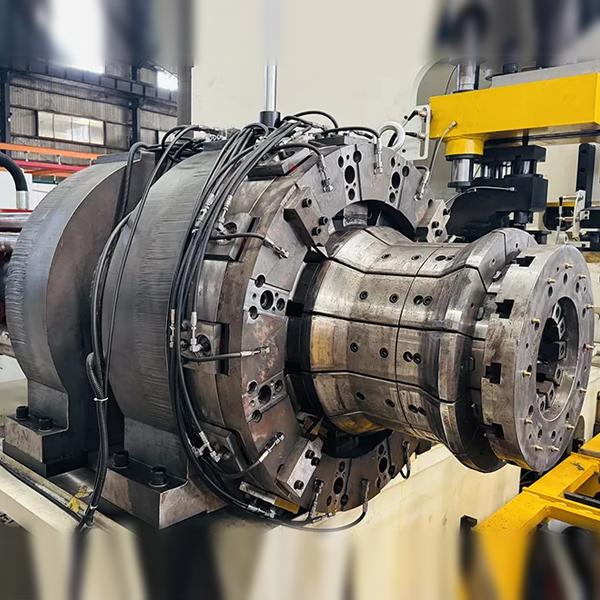

The trimming, planishing, end cutting, and re-rounding machine is a specialized piece of equipment for processing steel wheel rims after the butt welding stage. It includes multiple integrated components: weld trimmer, weld slag remover, weld seam planisher, and end cutting, along with an automated loading and unloading system, ensuring efficient handling of welded rims.

Component Functions

- Weld trimmer: Removes slag from both the inner and outer surfaces of the welded joint, creating a smooth and even surface

- Weld slag remover: Cleans up residual slag and debris from the welding process, preventing buildup and enhancing weld quality

- Weld seam planisher: Planishes and reinforces the welding seam for added durability of the weld

- Side trimmer (end cutting): Cuts off excess material from both ends of the welded joint, refining the rim to precise specifications

- Automated loading/unloading system: Integrates the operations of all four components, enabling seamless automation for increased wheel rim production efficiency