Wheel Rim Coiling Machine with Automatic Loading System

Wheel rim coiler machine used in steel wheel production line to form coiled hoops from flat strips

Wheel Rim Coiling Machine with Automatic Loading System

Wheel rim coiler machine used in steel wheel production line to form coiled hoops from flat strips

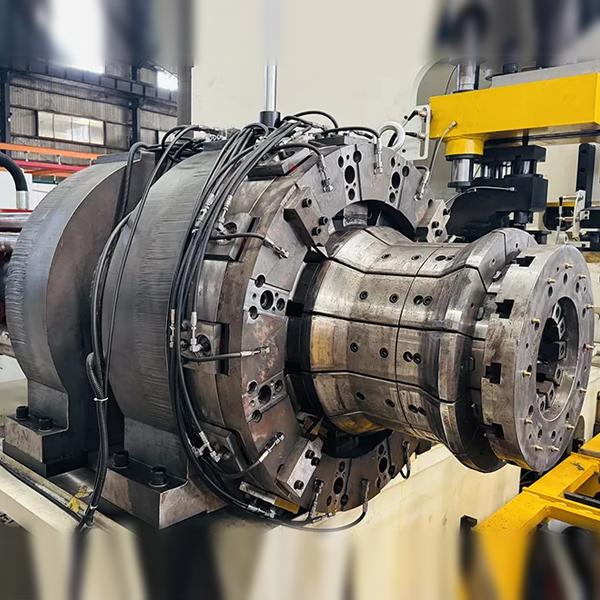

The wheel rim coiling machine is an essential piece of equipment in steel wheel production, designed to form flat steel strips into coiled hoops efficiently. Its automatic loading system optimizes the production of wheel rims by feeding the steel strips into the machine and ejecting coiled rims without manual intervention, reducing labor and improving workflow. This advanced coiling machine integrates three primary components to ensure precision shaping and high productivity: stamping, coiling and flattening.

Component Functions

- The stamping mechanism imprints essential markings onto the raw steel strip, including details like rim specifications, model numbers, manufacturer name, and production date. These marks ensure traceability and quality control across all rims.

- Responsible for forming the steel strip into a circular coiled hoop, the coiling mechanism creates a precise and uniform rim structure that serves as the base for subsequent manufacturing steps of wheel rims.

- After coiling, the flattening system presses the welded joint area, providing a smooth surface that enhances the strength of the final weld, which contributes to a stronger, secure, durable rim structure.